|

The cockpit side walls were next in line. This was easy to build !

It took

a little more work on the rear canopy deck, where there's a sliding track

rail. A bracket is attached to the rail, and a cross bar, which is attached

to the canopy. When the cranking handle is operated by the pilot, the

canopy slides on the rail equipment.

|

|

Cockpit

|

Click on photos below to

see larger photos |

|

|

Click on photo

below to see larger photos |

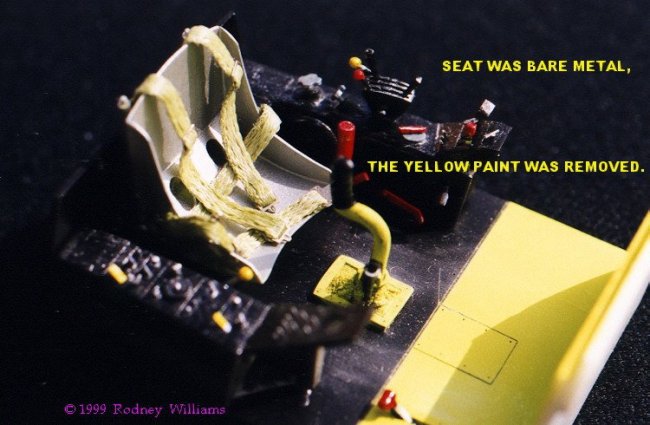

The cockpit master's were used as templates, so I could cut out all the

parts for the cockpit tub, side consuls, armor plate, head-rest, seat, and

several other items. I used Waldron photo-dials. One nice thing

about many

models I build is::::: I have learned how to glue the fuselage together,

correcting all the flaws in the cockpit area, then dry-fitting the cockpit

several times, so it slips up inside the fuselage, like a tailor-made glove.

Once all the painting is finished, the cockpit is put in, then the wings go

on.

You will see the seat painted the lemon-green color. I found out it was

bare-metal, so I removed the paint.

|

|

Engine and engine cowling

|

Click on photos below to

see larger photos |

|

|

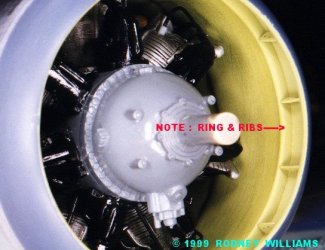

The finished engine is in, and I start adding the additional parts. The

exhaust stacks were temporary attached, so I knew they would fit on final

assembly. I found some aluminum tubing, for the cowling. Since then,

I

have had the cowling cast in one piece.

Rodney

|

|

|

|

" Building a

1/32 scale F4U-1A conversion to a F2G-1D Super Corsair"

Part 1

|

" Building a

1/32 scale F4U-1A conversion to a F2G-1D Super Corsair"

Part 3

|

" Building a

1/32 scale F4U-1A conversion to a F2G-1D Super Corsair"

Part 4

|

| Prop,

wing air intakes, engine and tail wheel |

Wings and canopy |

Finishing touches |

|

|